Mu dziko lomwe likusintha mofulumira kwambiri popanga zinthu zamakono, kulondola kudakali gawo lofunika kwambiri. Masiku ano, njira yatsopano yatsopano yakonzedwa kuti isinthe miyezo yamakampani: Precision Marble Three-Axis Gantry Platform, yomwe ndi njira yodabwitsa yopangira zinthu zomwe zimaphatikiza kukhazikika kwa granite yachilengedwe ndi kapangidwe ka makina apamwamba kuti zikwaniritse kulondola kwa micron komwe kale kunkaganiziridwa kuti sikungatheke m'mafakitale.

Sayansi Yomwe Imayambitsa Kukhazikika

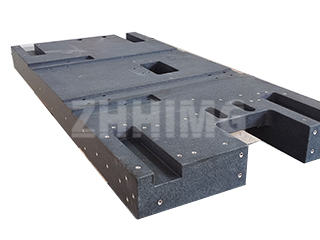

Pakati pa zinthu zosayembekezereka zomwe zachitika pa ukadaulo uwu pali zinthu zosayembekezereka zomwe mungasankhe: granite wachilengedwe. Maziko a miyala yamtengo wapatali ya 1565 x 1420 x 740 mm si okongola chabe—ndi yankho lasayansi ku vuto lakale losunga bata m'makina olondola kwambiri. "Kuchuluka kwa kutentha kwa granite (2.5 x 10^-6 /°C) komanso makhalidwe ake abwino kwambiri oletsa kutentha kumapereka maziko omwe amalimbana ndi kusinthasintha kwa kutentha kwa chilengedwe komanso kugwedezeka kwa makina kuposa nyumba zachitsulo zachikhalidwe," akufotokoza Dr. Emily Chen, injiniya wamkulu wa makina ku Precision Engineering Research Institute.

Ubwino wachilengedwe uwu umachokera mwachindunji ku ziwerengero za magwiridwe antchito zomwe zikutembenuza mitu yamakampani. Pulatifomuyi imakwaniritsa kubwerezabwereza kwa ±0.8 μm—kutanthauza kuti imatha kubwerera pamalo aliwonse ndi kupotoka kochepa kuposa kutalika kwa mafunde a kuwala kowoneka—ndi kulondola kwa malo a ±1.2 μm pambuyo pobwezeredwa, ndikukhazikitsa muyezo watsopano wa machitidwe owongolera mayendedwe.

Ukadaulo Wauinjiniya Pakuyenda

Kupitilira maziko ake okhazikika, kapangidwe ka gantry ka nsanja ya three-axis gantry kakuphatikiza zinthu zingapo zapadera. X-axis ili ndi makina oyendetsera awiri omwe amachotsa kusintha kwa torsional panthawi yoyenda mwachangu, pomwe ma axes onse a X ndi Y amapereka kuyenda kogwira mtima kwa 750 mm ndi ≤8 μm molunjika m'mabwalo onse opingasa komanso oimirira. Mlingo uwu wa kulondola kwa geometric umatsimikizira kuti ngakhale njira zovuta za 3D zimasunga kulondola kwa sub-micron.

Mphamvu ya kayendedwe ka makinawa imagwirizana bwino kwambiri ndi liwiro ndi kulondola. Ngakhale liwiro lake lalikulu la 1 mm/s lingawoneke ngati laling'ono, ndi loyenera kugwiritsa ntchito mapulogalamu omwe amafunikira kuwongolera bwino komanso kusanthula pang'onopang'ono—komwe kulondola ndikofunikira kuposa kuyenda mwachangu. Mosiyana ndi zimenezi, mphamvu ya 2 G yofulumizitsa imatsimikizira kugwira ntchito bwino kwa start-stop, kofunikira kwambiri kuti ipitirire patsogolo poyang'anira molondola.

Ndi mphamvu yonyamula katundu yolemera makilogalamu 40 komanso mphamvu ya 100 nm (0.0001 mm), nsanjayi imalumikiza kusiyana pakati pa kusinthasintha kwapadera ndi kulimba kwa mafakitale—kusinthasintha komwe kukupangitsa chidwi chachikulu m'magawo opanga zinthu.

Kusintha Makampani Ofunika Kwambiri

Zotsatira za kupita patsogolo kolondola kumeneku zikufalikira m'magawo angapo apamwamba aukadaulo:

Mu kupanga ma semiconductor, komwe ngakhale zolakwika za nanometer-scale zingapangitse kuti ma chips asagwire ntchito, kukhazikika kwa nsanjayi kukusinthira njira zowunikira ma wafer ndi photolithography. "Tikuwona kuchuluka kwa zilema zomwe zikupezeka zikukwera ndi 37% m'mayesero oyambirira," akutero Michael Torres, mainjiniya wamkulu wa njira zopangira zida za semiconductor. "Kugwedera kwa ma marble base kwachotsa kugwedezeka kwa micro-wobble komwe kale kunkabisa mawonekedwe a sub-50 nm."

Kupanga ma lens moyenera ndi chinthu china chopindulitsa. Njira zopukutira ndi kusonkhanitsa ma lens zomwe kale zinkafuna maola ambiri osinthira ndi manja, tsopano zitha kupangidwa zokha pogwiritsa ntchito malo a sub-micron a nsanjayi, kuchepetsa nthawi yopangira komanso kukonza magwiridwe antchito a ma lens.

Mu kafukufuku wa zamankhwala, nsanjayi ikuthandiza kupita patsogolo pakusintha kwa selo limodzi ndi kujambula zithunzi za microscopic zomwe zimakhala ndi mawonekedwe apamwamba kwambiri. Dr. Sarah Johnson wa ku Dipatimenti Yoyang'anira Zamankhwala ku Stanford akuti, "Kukhazikika kumeneku kumatithandiza kuyang'ana kwambiri kapangidwe ka maselo kwa nthawi yayitali, kujambula zithunzi zomwe zimawonetsa njira zamoyo zomwe zidabisidwa kale ndi kusuntha kwa zida."

Ntchito zina zofunika kwambiri zikuphatikizapo makina oyezera zinthu molondola kwambiri (CMMs), ma CD a microelectronics, ndi zida zapamwamba zofufuzira zasayansi—malo onse omwe kuphatikiza kwapadera kwa kulondola, kukhazikika, ndi mphamvu yonyamula katundu pa nsanjayi kumathetsa zopinga zaukadaulo zomwe zakhalapo kwa nthawi yayitali.

Tsogolo la Kupanga Zinthu Molondola Kwambiri

Pamene kupanga kukupitilirabe kukakamiza kwake kosalekeza kuti zinthu zizikhala zochepa komanso miyezo yapamwamba yogwirira ntchito, kufunikira kwa makina owongolera zinthu molondola kwambiri kudzawonjezeka. Pulatifomu ya Precision Marble Three-Axis Gantry sikuti imangosintha pang'onopang'ono koma kusintha kwakukulu pa momwe kulondola kumakwaniritsidwira - kugwiritsa ntchito zinthu zachilengedwe pamodzi ndi uinjiniya wapamwamba m'malo mongodalira makina ovuta ogwirira ntchito.

Kwa opanga omwe akukumana ndi mavuto a Industry 4.0, nsanja iyi imapereka chithunzithunzi cha tsogolo la uinjiniya wolondola. Ndi tsogolo pomwe malire pakati pa "kulondola kwa labotale" ndi "kupanga mafakitale" akupitirirabe kusokonekera, zomwe zimalola zatsopano zomwe zidzapange chilichonse kuyambira zamagetsi zam'badwo wotsatira mpaka zida zamankhwala zopulumutsa moyo.

Monga momwe katswiri wina wa zamakampani ananenera: "M'dziko lopanga zinthu molondola, kukhazikika si chinthu chokhacho—ndi maziko omwe zinthu zina zonse zapita patsogolo zimamangidwira. Nsanja iyi sikuti imangokweza zinthu zokha; imamanganso zonse."

Nthawi yotumizira: Okutobala-31-2025