M'maholo odekha a ma calibration laboratory, zipinda zotsukira za semiconductor, ndi malo oyezera zinthu m'mlengalenga, kusintha kwachete kukuchitika. Sikuyendetsedwa ndi mapulogalamu kapena masensa okha—koma ndi zipangizo zomwe zimapanga maziko a muyeso wokha. Patsogolo pa kusinthaku pali zida zoyezera zapamwamba za ceramic, kuphatikizapo ultra-stable ceramic air straight ruler ndi silicon-carbide (Si-SiC) parallelepiped ndi square. Izi si zida zokha; ndi zoyambitsa nthawi yatsopano kumene kukhazikika, kubwerezabwereza, ndi kusalowerera ndale kwa kutentha sizingakambiranedwe.

Kwa zaka zoposa makumi asanu, granite wakuda wakhala ukulamulira kwambiri njira yoyezera zinthu molondola. Kuchepa kwake kwachilengedwe, kutentha kochepa, komanso kusalala bwino kunapangitsa kuti ikhale chinthu chofunikira kwambiri pa mbale zapamwamba, masikweya, ndi m'mbali molunjika. Komabe pamene mafakitale akukankhira ku kulekerera kwa sub-micron komanso nanometer-scale—makamaka mu semiconductor lithography, space optics, ndi quantum computing—zofooka za granite zayamba kuonekera kwambiri. Ndi yolemera, yotheka kugwidwa ndi micro-chipping ikakhudzana mobwerezabwereza, ndipo, ngakhale kuti ili ndi mbiri yabwino, ikadali ndi kusinthasintha pang'ono kwa nthawi yayitali pansi pa katundu kapena kusinthasintha kwa chilengedwe.

Lowani mu zoumba zopangidwa ndi akatswiri: osati mbiya yosalimba ya malingaliro a tsiku ndi tsiku, koma zinthu zokhuthala, zofanana, zogwira ntchito bwino zomwe zimapangidwa pansi pa kutentha kwakukulu ndi kupsinjika. Pakati pa izi, magulu awiri amadziwika bwino pa ntchito za metrology: alumina yoyera kwambiri (Al₂O₃) ndi silicon carbide yolumikizidwa ndi reaction-bonded (Si-SiC). Ngakhale zonse ziwiri zimapereka kusintha kwakukulu kuposa zipangizo zachikhalidwe, zimagwira ntchito zosiyana - ndipo pamodzi, zimayimira m'mphepete mwa zomwe zingatheke mu metrology yozungulira.

Mwachitsanzo, tenga cholamulira cha mpweya chowongoka cha ceramic. Chopangidwa kuti chigwiritsidwe ntchito ndi magawo onyamula mpweya kapena ma interferometer optical, chida ichi chimafuna kulunjika kwabwino kwambiri, kulemera kochepa, komanso kutentha konse.olamulira a ceramic—yopangidwa kuti ikhale yosalala komanso yowongoka mkati mwa ±0.5 µm pamwamba pa 500 mm ndikupukutidwa kuti ikhale yolimba pansi pa Ra 0.02 µm—imapereka zomwezo. Kuchuluka kwawo kochepa (~3.6 g/cm³) kumachepetsa kufooka mu machitidwe oyesera amphamvu, pomwe chibadwa chawo chosakhala cha maginito, chosayendetsa magetsi chimachotsa kusokoneza m'malo ovuta amagetsi kapena maginito. Mu zida zowunikira za wafer kapena makonzedwe a laser tracker calibration, komwe ngakhale micron ya bow ingasinthe zotsatira, ceramic air straight ruler imapereka chidziwitso chokhazikika, chosagwira ntchito chomwe chimakhalabe chowona pakusintha kwa kutentha ndi machitidwe ogwirira ntchito.

Koma pamene kuuma kwakukulu ndi kusinthasintha kwa kutentha kukufunika—monga momwe zimakhalira mu mlengalenga, kulinganiza magalasi a telesikopu kapena kuyerekeza kwa laser cavity kwamphamvu—mainjiniya amagwiritsa ntchito zinthu zodziwika bwino monga silicon-carbide (Si-SiC) parallelepipe ndi sikweya. Si-SiC ndi imodzi mwa zinthu zolimba kwambiri zomwe zimadziwika, ndipo modulus ya Young imaposa 400 GPa—kuposa katatu kuposa chitsulo—ndipo kusinthasintha kwa kutentha kumafanana ndi aluminiyamu. Chofunika kwambiri, coefficient of thermal expansion (CTE) yake ikhoza kupangidwa kuti ifanane ndi magalasi owoneka bwino kapena ma silicon wafers, zomwe zimathandiza kuti pakhale kufalikira kwa kusiyana kwa zero m'magulu osakanikirana. Si-SiC sikweya yomwe imagwiritsidwa ntchito ngati master reference mu chida cha EUV lithography sichingosunga mawonekedwe ake—idzakana kusokonezeka ndi kutentha kapena kugwedezeka komwe kumachitika m'deralo.

Chomwe chimapangitsa kuti zinthuzi zitheke si zinthu zokha, komanso luso lopanga zida zoyezera za ceramic. Mwachitsanzo, makina olondola a Si-SiC amafunikira mawilo opukutira diamondi, nsanja za CNC za sub-micron, ndi njira zambiri zolumikizira zomwe zimachitika m'malo olamulidwa ndi kutentha. Ngakhale kupsinjika pang'ono kotsalira chifukwa cha sintering yosayenera kungayambitse kusokonekera kwa makina pambuyo pa makina. Ichi ndichifukwa chake opanga ochepa padziko lonse lapansi amaphatikiza kapangidwe ka zinthu, kupanga molondola, ndi metrology yomaliza pansi pa denga limodzi—mphamvu yomwe imasiyanitsa opanga enieni a metrology ndi ogulitsa wamba a ceramic.

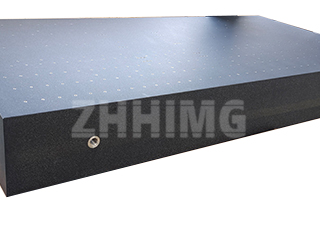

Ku ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (ZHHIMG), kuphatikiza koyima kumeneku ndikofunikira kwambiri pa ntchito yathu. Zipangizo zathu zoyezera za ceramic—kuphatikizapo mitundu ya ceramic air straight ruler yovomerezeka ku DIN 874 Grade AA ndi zinthu zopangidwa ndi silicon-carbide (Si-Si-C) parallelepipe ndi square pipe zomwe zimatsatiridwa ndi miyezo ya PTB ndi NIST—zimapangidwa m'zipinda zoyera za ISO Class 7 pogwiritsa ntchito njira zoyezera ndi zomaliza. Chigawo chilichonse chimatsimikiziridwa bwino ndi interferometric, kutsimikizika kwa CMM kwa geometric tolerances (flatness, parallelism, perpendicularity), ndi kuyesedwa kwa umphumphu wa pamwamba musanatumize. Zotsatira zake ndi chinthu choyimira chomwe sichimakwaniritsa zofunikira zokha—chimapitirira nthawi zonse m'magulu onse.

Kufunika kwa magwiridwe antchito otere kukuchulukirachulukira. Pakupanga ma semiconductor, machitidwe a EUV ndi high-NA lithography amafuna kuti mapangidwe a aluminiyamu akhale olimba mpaka mkati mwa ma nanometer makumi angapo pa mtunda wa mita - sizingatheke popanda mgwirizano wa kutentha ndi makina a Si-SiC. Mu ndege, mipando yowunikira ya satellite yopangidwa ndi ma ceramic references imatsimikizira kukhazikika pa obiti ngakhale kutentha kwambiri. Ngakhale m'magawo omwe akutuluka monga kuzindikira mafunde okoka kapena chitukuko cha wotchi ya atomiki, komwe kukhazikika kwa mulingo wa picometer ndikofunikira, zinthu za ceramic ndi Si-SiC metrology zikukhala zofunika kwambiri.

Chofunika kwambiri, zida izi zimayang'ananso kukhazikika ndi mtengo wonse wa umwini. Ngakhale kuti ndalama zoyamba zomwe zimagwiritsidwa ntchito mu silicon-carbide parallelepiped yolondola kwambiri zitha kupitirira zomwe zimagwiritsidwa ntchito ndi granite, nthawi yake yogwirira ntchito imatha kupitilira nthawi 5-10 m'malo omwe amagwiritsidwa ntchito kwambiri. Sichifuna mafuta, chimalimbana ndi zosungunulira zonse wamba ndi ma plasma, ndipo sichifunikiranso kukonzedwanso chifukwa cha kuyamwa chinyezi—mosiyana ndi chitsulo chopangidwa kapena granite zina. Kwa oyang'anira abwino omwe amagwira ntchito motsatira AS9100, ISO 13485, kapena miyezo ya SEMI, kudalirika kumeneku kumatanthauza mwachindunji kuchepa kwa nthawi yogwira ntchito, zochepa zomwe zapezeka mu kafukufuku, komanso chidaliro chachikulu cha makasitomala.

Komanso, kukongola ndi kukongola kwa zida izi sikuyenera kunyalanyazidwa. Sikweya yopukutidwa ya Si-SiC imawala ndi kunyezimira kwachitsulo koma imalemera pang'ono kuposa chitsulo. Wolamulira wowongoka wa ceramic air straight amamveka wolimba koma amanyamuka mosavuta—ndiye woyenera kutsimikiziridwa ndi manja m'malo opapatiza. Makhalidwe amenewa okhazikika pa anthu ndi ofunika m'ma laboratories enieni komwe ergonomics ndi kugwiritsa ntchito mosavuta zimakhudza kayendetsedwe ka ntchito tsiku ndi tsiku.

Kodi zida zoyezera za ceramic zikukonzanso kulondola kwambiri? Yankho lili mu deta—ndi mndandanda womwe ukukula wa atsogoleri apadziko lonse lapansi omwe tsopano akuwatchula ngati muyezo. Kuchokera ku mabungwe adziko lonse oyesa zinthu zoyezera omwe akutsimikizira miyezo ya kutalika kwa mbadwo wotsatira mpaka kwa ogulitsa a Tier 1 omwe amatsimikizira zigawo za EV drivetrain, kusinthaku n'komveka bwino: pamene kusatsimikizika kuyenera kuchepetsedwa, mainjiniya amakhulupirira zoyezera zopangidwa ndi makina.

Ndipo pamene mafakitale akupitirizabe ulendo wawo wosalekeza wopita ku ulamuliro wa atomiki, chowonadi chimodzi chimakhala chosatsutsika: tsogolo la muyeso silidzasemedwa kuchokera ku miyala kapena kupangidwa ndi chitsulo. Lidzasiyidwa, kuphwanyidwa, ndi kupukutidwa ndi ceramic—ndi silicon carbide.

ZHHIMG ndi kampani yodziwika bwino padziko lonse lapansi yopanga njira zoyezera za ceramic ndi silicon-carbide. Imagwira ntchito kwambiri ndi zida zoyezera za ceramic, ceramic air straight ruler, ndi high precision silicon-carbide (Si-SiC) parallelepiped ndi square components, ndipo imapereka zinthu zovomerezeka bwino, zogwiritsidwa ntchito mu labotale za semiconductor, aerospace, defense, ndi kafukufuku wasayansi. Yothandizidwa ndi ISO 9001, ISO 14001, ndi CE certifications, zinthu zathu zimadaliridwa ndi makampani otsogola padziko lonse lapansi. Onani zambiri zathu za metrology pawww.zhhimg.com.

Nthawi yotumizira: Disembala-05-2025