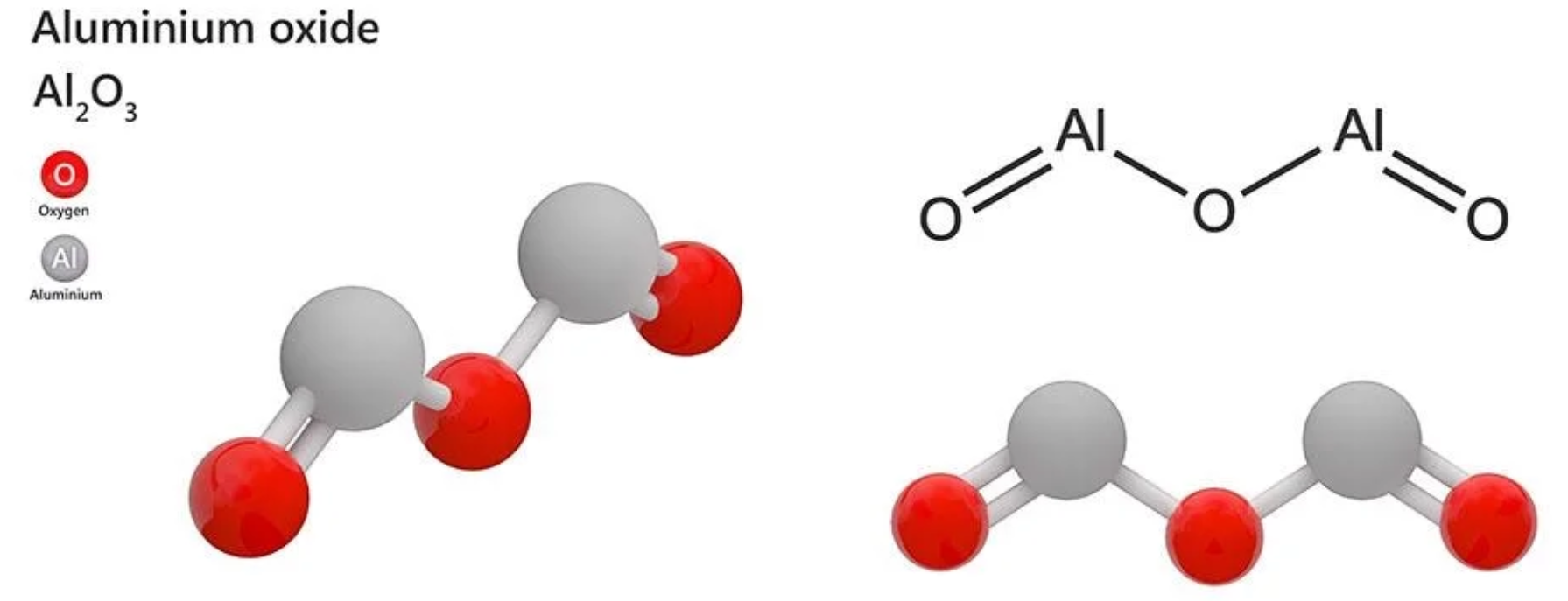

♦ Alumina (Al2O3)

Magawo olondola a ceramic opangidwa ndi ZhongHui Intelligent Manufacturing Group (ZHHIMG) amatha kupangidwa ndi zida za ceramic zoyera kwambiri, 92 ~ 97% alumina, 99.5% alumina, > 99.9% alumina, ndi CIP ozizira isostatic kukanikiza. Kutentha kwakukulu kwa sintering ndi makina olondola, kulondola kwa ± 0.001mm, kusalala mpaka Ra0.1, kugwiritsa ntchito kutentha mpaka madigiri 1600. Mitundu yosiyanasiyana ya ceramics ikhoza kupangidwa malinga ndi zofuna za makasitomala, monga: zakuda, zoyera, beige, zofiira zakuda, etc. Mbali zolondola za ceramic zopangidwa ndi kampani yathu zimagonjetsedwa ndi kutentha kwakukulu, dzimbiri, kuvala ndi kutsekemera, ndipo zingagwiritsidwe ntchito kwa nthawi yayitali kutentha kwakukulu, vacuum ndi mpweya wowononga mpweya.

Amagwiritsidwa ntchito kwambiri pazida zosiyanasiyana zopangira semiconductor: Mafelemu (bulaketi ya ceramic), Substrate (base), Arm/ Bridge(manipulator), , Mechanical Components ndi Ceramic Air Bearing.

| Dzina lazogulitsa | High Purity 99 Alumina Ceramic Square Tube / Pipe / Ndodo | |||||

| Mlozera | Chigawo | 85% Al2O3 | 95% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | |

| Kuchulukana | g/cm3 | 3.3 | 3.65 | 3.8 | 3.9 | |

| Kumwa Madzi | % | <0.1 | <0.1 | 0 | 0 | |

| Sintered Kutentha | ℃ | 1620 | 1650 | 1800 | 1800 | |

| Kuuma | Mohs | 7 | 9 | 9 | 9 | |

| Kupindika Mphamvu (20 ℃)) | Mpa | 200 | 300 | 340 | 360 | |

| Compressive Mphamvu | Kgf/cm2 | 10000 | 25000 | 30000 | 30000 | |

| Kutentha kwa Nthawi Yaitali Yogwira Ntchito | ℃ | 1350 | 1400 | 1600 | 1650 | |

| Max. Kutentha kwa Ntchito | ℃ | 1450 | 1600 | 1800 | 1800 | |

| Kukaniza kwa Voliyumu | 20 ℃ | Ω . cm3 | > 1013 | > 1013 | > 1013 | > 1013 |

| 100 ℃ | 1012-1013 | 1012-1013 | 1012-1013 | 1012-1013 | ||

| 300 ℃ | > 109 | > 1010 | > 1012 | > 1012 | ||

Kugwiritsa ntchito zida za aluminiyamu zoyera kwambiri:

1. Amagwiritsidwa ntchito ku zida za semiconductor: ceramic vacuum chuck, kudula disc, kuyeretsa diski, ceramic CHUCK.

2. Zigawo zosinthira zophatikizika: zophatikizika zonyamula ma chucks, ma disc odulira, ma disks otsuka, makapu opangira ma wafer.

3. LED / LCD lathyathyathya gulu anasonyeza makampani: ceramic nozzle, ceramic kugaya chimbale, LIFT PIN, Pin njanji.

4. Kuyankhulana kwa kuwala, mafakitale a dzuwa: machubu a ceramic, ndodo za ceramic, makina osindikizira osindikizira a ceramic scrapers.

5. Zigawo zosagwirizana ndi kutentha ndi magetsi: zitsulo za ceramic.

Pakali pano, zoumba za aluminiyamu okusayidi akhoza kugawidwa mu chiyero mkulu ndi zadothi wamba. Mndandanda wapamwamba wa aluminiyumu wa oxide ceramics wa ceramic umatanthawuza zinthu za ceramic zomwe zili ndi zoposa 99.9% Al₂O₃. Chifukwa cha kutentha kwake kwa 1650 - 1990 ° C ndi kutalika kwake kwa 1 ~ 6μm, nthawi zambiri amasinthidwa kukhala galasi losakanikirana m'malo mwa platinamu crucible: yomwe ingagwiritsidwe ntchito ngati chubu la sodium chifukwa cha kuwala kwake komanso kukana kwa dzimbiri kuzitsulo zamchere. M'makampani amagetsi, amatha kugwiritsidwa ntchito ngati zida zotchingira ma frequency amtundu wa IC. Malinga ndi zomwe zili mu aluminiyumu oxide, mndandanda wamba wa aluminiyamu wa ceramic wamba ukhoza kugawidwa muzoumba 99, 95 ceramics, 90 ceramics ndi 85 ceramics. Nthawi zina, zoumba ndi 80% kapena 75% ya okusayidi zotayidwa amatchedwanso wamba zotayidwa okusayidi ceramic mndandanda. Pakati pawo, 99 aluminiyamu okusayidi ceramic zinthu ntchito kupanga mkulu kutentha crucible, chubu ng'anjo yowotcha moto ndi zipangizo kuvala zosagwira, monga mayendedwe ceramic, zisindikizo ceramic ndi mbale valavu. 95 aluminiyamu ceramics amagwiritsidwa ntchito makamaka ngati dzimbiri zosamva kuvala mbali. 85 ceramics nthawi zambiri imasakanizidwa muzinthu zina, potero kumapangitsa kuti magetsi azikhala ndi mphamvu zamakina. Itha kugwiritsa ntchito molybdenum, niobium, tantalum ndi zisindikizo zina zachitsulo, ndipo zina zimagwiritsidwa ntchito ngati zida zamagetsi.

| Katundu Wabwino (mtengo Woyimira) | Dzina lazogulitsa | Chithunzi cha AES-12 | Chithunzi cha AES-11 | AES-11C | AES-11F | AES-22S | AES-23 | AL-31-03 | |

| Chemical Composition Low-Sodium Easy Sintering Product | H₂O | % | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Sekani | % | 0.1 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |

| Fe₂0₃ | % | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | |

| SiO₂ | % | 0.03 | 0.03 | 0.03 | 0.03 | 0.02 | 0.04 | 0.04 | |

| Na₂O | % | 0.04 | 0.04 | 0.04 | 0.04 | 0.02 | 0.04 | 0.03 | |

| MgO* | % | - | 0.11 | 0.05 | 0.05 | - | - | - | |

| Al₂0₃ | % | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | |

| Medium Particle Diameter (MT-3300, njira yowunikira laser) | μm | 0.44 | 0.43 | 0.39 | 0.47 | 1.1 | 2.2 | 3 | |

| α Crystal Kukula | μm | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 ~ 1.0 | 0.3-4 | 0.3-4 | |

| Kupanga Density ** | g/cm³ | 2.22 | 2.22 | 2.2 | 2.17 | 2.35 | 2.57 | 2.56 | |

| Sintering Density ** | g/cm³ | 3.88 | 3.93 | 3.94 | 3.93 | 3.88 | 3.77 | 3.22 | |

| Kuchepa kwa Mzere wa Sintering** | % | 17 | 17 | 18 | 18 | 15 | 12 | 7 | |

* MgO siyidaphatikizidwe pakuwerengera chiyero cha Al₂O₃.

* Palibe makulitsidwe ufa 29.4MPa (300kg/cm²), sintering kutentha ndi 1600°C.

AES-11 / 11C / 11F: Onjezani 0.05 ~ 0.1% MgO, sinterability ndi yabwino kwambiri, choncho imagwira ntchito pazitsulo zotayidwa za aluminium oxide ndi chiyero choposa 99%.

AES-22S: Imadziwika ndi kachulukidwe kakang'ono kapangidwe kake komanso kutsika pang'ono kwa mzere wa sintering, imagwira ntchito pakupanga mawonekedwe otsetsereka ndi zinthu zina zazikuluzikulu zolondola kwambiri.

AES-23 / AES-31-03: Ili ndi mawonekedwe apamwamba kwambiri, thixotropy komanso mamasukidwe otsika kuposa AES-22S. yoyamba imagwiritsidwa ntchito ku zitsulo za ceramic pamene yotsirizirayi imagwiritsidwa ntchito ngati chochepetsera madzi pazinthu zotetezera moto, kutchuka.

♦ Makhalidwe a Silicon Carbide (SiC).

| General Makhalidwe | Kuyera kwa zigawo zikuluzikulu (wt%) | 97 | |

| Mtundu | Wakuda | ||

| Kachulukidwe (g/cm³) | 3.1 | ||

| Kumwa madzi (%) | 0 | ||

| Makhalidwe Amakina | Flexural mphamvu (MPa) | 400 | |

| Young modulus (GPA) | 400 | ||

| Vickers kuuma (GPA) | 20 | ||

| Thermal Makhalidwe | Kutentha kwambiri kwa ntchito (°C) | 1600 | |

| Kuwonjezela kwamafuta kokwana | RT~500°C | 3.9 | |

| (1/°C x 10-6) | RT~800°C | 4.3 | |

| Thermal conductivity (W/m x K) | 130 110 | ||

| Thermal shock resistance ΔT (°C) | 300 | ||

| Makhalidwe Amagetsi | Kuchuluka kwa resistivity | 25°C | 3 x106 pa |

| 300 ° C | - | ||

| 500°C | - | ||

| 800°C | - | ||

| Dielectric nthawi zonse | 10 GHz | - | |

| Kutayika kwa dielectric (x 10-4) | - | ||

| Q Factor (x 104) | - | ||

| Dielectric breakdown voltage (KV/mm) | - | ||

♦Silicon Nitride Ceramic

| Zakuthupi | Chigawo | Si₃N₄ |

| Sintering Njira | - | Kupanikizika kwa Gasi Sintered |

| Kuchulukana | g/cm³ | 3.22 |

| Mtundu | - | Imvi Yakuda |

| Kuchuluka kwa Madzi | % | 0 |

| Young Modulus | Gpa | 290 |

| Vickers Kuuma | Gpa | 18-20 |

| Compressive Mphamvu | Mpa | 2200 |

| Kupindika Mphamvu | Mpa | 650 |

| Thermal Conductivity | W/mK | 25 |

| Thermal Shock Resistance | Δ (°C) | 450-650 |

| Kutentha Kwambiri Kwambiri | °C | 1200 |

| Kukaniza kwa Voliyumu | Ω·cm | > 10 ^ 14 |

| Dielectric Constant | - | 8.2 |

| Mphamvu ya Dielectric | kV/mm | 16 |