Pakatikati pa mafakitale opanga makina ndi metrology pali chida choyambira: Plate ya Cast Iron Surface. Zida zofotokozera za pulanizi ndizofunikira kwambiri pakuwunika kolondola kwa zida zogwirira ntchito, kulemba molondola, komanso kukhala ngati ma benchmark okhazikika pakukhazikitsa zida zamakina. Ku ZHHIMG®, kudzipereka kwathu pakulondola kwambiri kumapitilira kupitilira zida zathu zodziwika bwino za granite kupita ku miyezo yokhazikika yomwe imayang'anira zida zonse zofunika za metrology. Kumvetsetsa kachitidwe mosamala - kuyambira pakuyika mpaka kuyika - ndikofunikira kwambiri pakuwonetsetsa kuti zinthu zili bwino komanso zautali wazinthu zofunika kwambiri zapashopu iyi.

Chilango cha Foundry: Kusamala mu Cast Iron Casting

Kupanga mbale zapamwamba zachitsulo zam'mwamba zimayamba ndi chilango chokhwima mu maziko. Ogwiritsa ntchito ayenera kutsatira mosamalitsa njira yoyendetsedwa yoyendetsedwa ndi kuphweka komanso kufanana. Izi zikuphatikizapo kupanga mapangidwe omwe amachepetsa kuchuluka kwa malo olekanitsa ndi mchenga wa mchenga ndikuwonetsetsa kuti ma angles apangidwe bwino komanso makulidwe a khoma. Kusankha njira yoyenera yolowera pakhomo ndikofunikira; ziyenera kutsimikizira kukhazikika kotsatizana, zomwe zimatsogolera ku kuponyedwa kofanana, kochepetsetsa kupsinjika.

Chofunika kwambiri, mtundu wa mchenga wowuma umakhudza mwachindunji kuponyera komaliza. Mchenga wosakaniza uyenera kukhala ndi permeability kwambiri, mphamvu yonyowa, fluidity, plasticity, ndi collapsibility. Izi zimatheka potsatira mosamalitsa ndondomeko ya kadyedwe ka zinthu—mchenga wakale, mchenga watsopano, dongo, ufa wa malasha, ndi madzi—ndi kulamulira nthawi yosanganikirana bwino pa mphindi zisanu ndi chimodzi kapena zisanu ndi ziwiri. Mchenga wosakanikirana umapumula ndikusefa kuti upititse patsogolo mphamvu zake ndi madzimadzi musanagwiritse ntchito.

Kuthira kumafuna kuyang'ana kosagwedezeka. Chitsulo chosungunula chiyenera kubayidwa bwino ndi kuchotsedwa bwino musanayambe kuthira. Kuyenda kosalekeza ndi kokhazikika ndikofunikira kuti tipewe zolakwika monga kukokoloka kwa mchenga ndi kupanga maenje a mchenga. Kuchita mwachangu pakutayikira kulikonse ndikofunikira kuti mupewe zovuta zazikulu monga zotsekera ozizira komanso kuthira kosakwanira. Pomaliza, kuyeretsa mosamala kumawonetsetsa kuti kuponyedwa koziziritsa kumachotsedwa mu nkhungu popanda kuwonongeka, kumapereka malo opanda cholakwika choyambirira.

Kupanga, Zowonongeka, ndi Kachulukidwe: Kuwonetsetsa Kukhazikika Kwamapangidwe

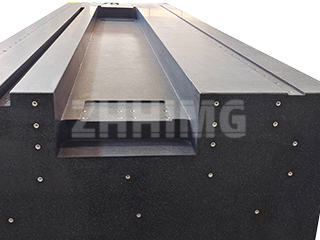

Pulatifomu yachitsulo yapamwamba kwambiri imapangidwa kuti ipirire. Nthawi zambiri amapangidwa ngati mbali imodzi kapena ngati bokosi, malo awo ogwirira ntchito amakhala amzere kapena amakona anayi. Kukhazikika kwapangidwe kumadalira kwambiri zinthu monga makoma am'mbali ndi nthiti zolimbitsa, zomwe ziyenera kukulitsidwa molingana ndi mphamvu yonyamulira yofunikira komanso kalasi yolondola. Kutalika kwa nthiti zomangirirazi—kaya ndi theka la nthiti, nthiti yonse, kapena nthiti yafulati—kumapereka mphamvu yofunikira ndi chichirikizo.

Ngakhale ndi zowongolera zolimba kwambiri, zolakwika zazing'ono zimatha kuchitika. Pakuti nsanja m'munsimu olondola giredi “0,” makampani mfundo kulola kukonza plugging ang'onoang'ono mchenga mabowo (m'mimba mwake zosakwana 14 mm) ntchito zinthu zomwezo, malinga kukonza zinthu kuuma ndi m'munsi kuposa chitsulo ozungulira. Komabe, malo ogwirira ntchito ayenera kukhala opanda zolakwika zazikulu, kuphatikizapo ming'alu, porosity, slag inclusions, ndi shrinkage cavities, ndipo malo oponyera ayenera kukhala osalala ndi utoto womamatira mwamphamvu. Kusankha nsanja yomwe yakhala ikukalamba mwachilengedwe kapena chithandizo cha kutentha kwachilengedwe ndikofunikira, chifukwa njirazi zimachepetsa kupsinjika kwamkati ndikuletsa kusinthika kwa diagonal mtsogolo.

Kuyika ndi Kukonza: Kusunga Zolondola

Pulatifomu yachitsulo choponyedwa, mosasamala kanthu za ubwino wake, ndi yolondola monga kuyika kwake. Iyenera kukhala yopingasa ndi katundu wogawidwa mofanana kumbali zonse zothandizira, zomwe zimatheka pogwiritsa ntchito mapazi osinthika a bulaketi yothandizira. Njira yokwezera iyi, motsogozedwa ndi mulingo wamagetsi wolondola kwambiri kapena mulingo wa chimango, ndi wofunikira kuti ukwaniritse kulondola kwake.

Kuti mukhale olondola, chilengedwe ndichofunikira. Kutentha kogwira ntchito kuyenera kusungidwa mozungulira 20 ℃ (± 5 ℃), ndipo kugwedezeka kuyenera kupewedwa. Ntchito iliyonse isanayambe, pamwamba pake iyenera kutsukidwa bwino kuti muchotse mchenga wotsalira, mafuta, mafuta, ndi dzimbiri, chifukwa ngakhale zowononga zazing'ono zimasokoneza kulondola. Malo apamwamba kwambiri, kapena osalala, ndi ofunikira kuti akhale ndi moyo wautali.

Pogwiritsa ntchito moyenera ndikusungirako mosamala, popewa kuzizira, kuwononga, kapena kutentha kwambiri, malo ogwirira ntchito achitsulo chachitsulo amatha kusungidwa kwa zaka ziwiri kapena kuposerapo. Mapangidwe a nsanja okha akhoza kukhala kwa zaka zambiri. Ngati kulondola kutsika, kumatha kubwezeretsedwanso kwathunthu kudzera mukusintha kwa akatswiri kapena kubwezeretsanso (kukwapula). Kuyang'ana nthawi zonse motsutsana ndi mulingo wake ndikofunikira, chifukwa kugwiritsa ntchito mbale yocheperako kungayambitse miyeso ndikusokoneza mtundu wa chinthu chomaliza.

Monga chida chofunikira pamagalimoto, zakuthambo, zida, ndi makina olemera, nsanja yachitsulo ndi umboni wakuti kulondola kumamangidwa kuchokera pansi.

Nthawi yotumiza: Oct-31-2025