M'madera monga kupanga semiconductor ndi zida zoyezera molondola, kulondola kwa nsanja za granite kumatsimikizira mwachindunji momwe zida zimagwirira ntchito. Kuonetsetsa kuti kulondola kwa pulatifomu kumagwirizana ndi miyezo, kuyesayesa kuyenera kupangidwa kuchokera ku mbali ziwiri: kuzindikira zizindikiro zazikulu ndi kutsata miyezo yoyenera. pa

Kuzindikira kwachizindikiro chapakati: Kuwongolera kwamitundu yambiri kulondola

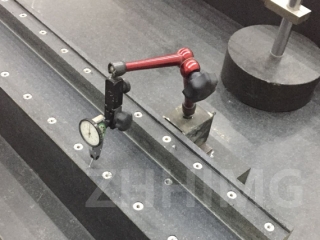

Kuzindikira kuyandama: Kuzindikira "kusalala" kwa ndege yolozera

Flatness ndiye chizindikiro chachikulu cha nsanja zolondola za granite, ndipo nthawi zambiri amayezedwa ndi laser interferometers kapena milingo yamagetsi. Laser interferometer akhoza ndendende kuyeza miniti undulations pa nsanja pamwamba potulutsa laser mtengo ndi kugwiritsa ntchito mfundo ya kusokoneza kuwala, ndi kulondola kufika pa mlingo waung'ono micron. Mulingo wamagetsi umayesa kusuntha kangapo ndikujambulitsa mapu amitundu itatu papulatifomu kuti awone ngati pali zotuluka kapena zopindika. Mwachitsanzo, mapulaneti a granite omwe amagwiritsidwa ntchito mu makina a semiconductor photolithography amayenera kukhala ndi flatness ± 0.5μm/m, kutanthauza kuti kusiyana kwa msinkhu mkati mwa 1 mita kutalika sikuyenera kupitirira theka la micrometer. Pokhapokha pogwiritsa ntchito zida zodziwira zolondola kwambiri momwe mulingo wokhazikikawu ungatsimikiziridwe. pa

2. Kuzindikira mowongoka: Onetsetsani "kuwongoka" kwa kayendedwe ka mzere

Kwa nsanja zomwe zimanyamula zida zoyenda bwino, kuwongoka ndikofunikira. Njira zodziwika bwino zodziwira ndi waya kapena laser collimator. Njira yamawaya imaphatikizapo kuyimitsa mawaya achitsulo apamwamba kwambiri ndikufanizira kusiyana pakati pa nsanja pamwamba ndi mawaya achitsulo kuti adziwe kuwongoka. Laser collimator imagwiritsa ntchito mizere yofalikira ya laser kuti izindikire cholakwika cha mzere woyikira njanji yowongolera nsanja. Ngati kuwongoka sikungafanane ndi muyezo, kumapangitsa kuti zida zisunthike panthawi yosuntha, zomwe zimakhudza kuwongolera kapena kuyeza kulondola. pa

3. Kuzindikira roughness: Onetsetsani "fineness" yokhudzana

Kuuma kwapamwamba kwa nsanja kumakhudza kukwanira kwa chigawocho. Nthawi zambiri, stylus roughness mita kapena microscope ya kuwala imagwiritsidwa ntchito pozindikira. Chida chamtundu wa stylus chimalemba kusintha kwa kutalika kwa mawonekedwe ang'onoang'ono polumikizana ndi nsanja ndi probe yabwino. Ma microscopes owoneka amatha kuyang'ana mwachindunji mawonekedwe apamwamba. M'mapulogalamu apamwamba kwambiri, kuuma kwapamwamba kwa mapulaneti a granite kumafunika kuwongoleredwa pa Ra≤0.05μm, yomwe imakhala yofanana ndi galasi, kuonetsetsa kuti zigawo zolondola zimagwirizana bwino panthawi yoika ndikupewa kugwedezeka kapena kusamuka chifukwa cha mipata. pa

Miyezo yolondola imatsatira: mayendedwe apadziko lonse lapansi ndikuwongolera mkati mwabizinesi

Pakalipano, padziko lonse lapansi, miyezo ya ISO 25178 ndi GB/T 24632 imagwiritsidwa ntchito kwambiri ngati maziko otsimikizira kulondola kwa nsanja za granite, ndipo pali magulu omveka bwino azizindikiro monga flatness ndi kuwongoka. Kuphatikiza apo, mabizinesi opangira zinthu zapamwamba nthawi zambiri amakhazikitsa malamulo okhwima amkati. Mwachitsanzo, kufunikira kwa flatness kwa nsanja ya granite yamakina a Photolithography ndi 30% apamwamba kuposa muyezo wapadziko lonse lapansi. Poyesa mayeso, deta yoyezedwa iyenera kufananizidwa ndi miyezo yofananira. Mapulatifomu okhawo omwe amatsatira mokwanira miyezo angatsimikizire kugwira ntchito mokhazikika pazida zolondola. pa

Kuyang'ana kulondola kwa nsanja za granite ndi ntchito yokhazikika. Pokhapokha poyesa mosamalitsa zizindikiro zazikuluzikulu monga flatness, kuwongoka, ndi roughness pamwamba, ndi kutsatira mfundo za mayiko ndi mabizinesi, mwatsatanetsatane mkulu ndi kudalirika kwa nsanja angatsimikizidwe, kuyika maziko olimba a minda yapamwamba yopangira zinthu monga semiconductors ndi zida zolondola.

Nthawi yotumiza: May-21-2025