Pamakina a picosecond-level laser cholemba makina, kulondola ndiye chizindikiro chachikulu pakuwunika momwe zida zimagwirira ntchito. Pansi, monga chonyamulira chachikulu cha dongosolo la laser ndi zigawo zolondola, zinthu zake zimakhudza mwachindunji kukhazikika kwa kukonza kulondola. Granite ndi chitsulo choponyedwa, monga zida ziwiri zoyambira, zimakhala ndi kusiyana kwakukulu pamayendedwe olondola ochepetsera panthawi ya picosecond-level Ultra-fine processing. Nkhaniyi isanthula mozama ubwino wa machitidwe ndi kuipa kwa awiriwa kuti apereke maziko asayansi okweza zida. pa

Zinthu zakuthupi zimatsimikizira maziko olondola

Granite kwenikweni ndi mwala woyaka moto womwe umapangidwa kudzera munjira za geological pazaka mazana mamiliyoni ambiri. Kapangidwe kake ka kristalo kamkati kake kamakhala kowuma komanso kofananira, komwe kamakhala kocheperako kocheperako ngati 0.5-8 × 10⁻⁶/℃, kufananizidwa ndi ma alloys olondola monga chitsulo cha indium. Khalidweli limapangitsa kusintha kwake kowoneka bwino kukhala kosafunikira pamene kutentha kozungulira kumasinthasintha, kupeweratu njira yowunikira komanso zolakwika zamakina zomwe zimayambitsidwa ndi kufalikira kwamafuta ndi kutsika. Kuphatikiza apo, kachulukidwe ka granite ndi wokwera kwambiri mpaka 2.6-2.8g/cm³, yomwe mwachilengedwe imakhala ndi mphamvu yoyamwa bwino kwambiri. Imatha kutsitsa mwachangu kugwedezeka kwapang'onopang'ono komwe kumapangidwa pakukonza laser, kuwonetsetsa kukhazikika kwa mawonekedwe owoneka bwino komanso magawo osuntha. pa

Maziko a cast iron amagwiritsidwa ntchito kwambiri chifukwa chakuchita bwino komanso mtengo wake. Mapangidwe amtundu wa flake graphite wa chitsulo chotuwira amachipangitsa kukhala ndi magwiridwe antchito ena, omwe amatha kuyamwa pafupifupi 30% mpaka 50% ya mphamvu yakugwedezeka. Komabe, coefficient of thermal expansion of cast iron iron is about 10-12 × 10⁻⁶/℃, yomwe ndi 2-3 nthawi ya granite. Pansi pa kudzikundikira kwa kutentha komwe kumapangidwa ndi nthawi yayitali yosalekeza, mapindikidwe amtundu amatha kuchitika. Pakalipano, pali kuponyera kupsinjika mkati mwachitsulo chosungunuka. Pamene kupsinjika kumatulutsidwa panthawi yogwiritsira ntchito, kungayambitse kusintha kosasinthika mu flatness ndi perpendicularity ya maziko. pa

Njira yolondola yochepetsera mumsewu wa picosecond

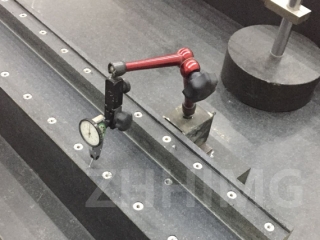

Picosecond laser processing, yokhala ndi mawonekedwe amfupi-fupi kwambiri, imatha kukwaniritsa bwino pamlingo wa micron kapena mulingo wa nanometer, komanso imabweretsanso zofunikira pakukhazikika kwa zida. Maziko a granite, okhala ndi mawonekedwe ake okhazikika amkati, amatha kuwongolera kugwedezeka kwapang'onopang'ono pamlingo wa sub-micron pansi pa mphamvu ya laser yapafupipafupi, ndikusunga kulondola kwapang'onopang'ono kwa laser. Deta yoyezedwa ikuwonetsa kuti makina ojambulira laser okhala ndi maziko a granite amakhalabe ndi kupatuka kwa mzere m'lifupi mwake mkati mwa ± 0.5μm pambuyo pakukonza kosalekeza kwa maola 8 kwa picosecond. pa

Chitsulo chachitsulo chikawonetsedwa ndi kugwedezeka kwakukulu kwa picosecond laser, kapangidwe kake ka mkati kamakhala ndi kutopa kwapang'onopang'ono chifukwa cha kukhudzidwa kosalekeza, zomwe zimapangitsa kuchepa kwa kulimba kwa maziko. Kuyang'anira deta kuchokera kumakampani opanga ma semiconductor kukuwonetsa kuti pakatha miyezi isanu ndi umodzi yogwira ntchito, kuwongolera kulondola kwa zida zokhala ndi zitsulo zotayira kumafika 12%, zomwe zimawonetsedwa makamaka ngati kuwonjezeka kwaukali kwa m'mphepete mwa mzere komanso kukulitsa zolakwika zoyika. Pakalipano, chitsulo chosungunuka chimakhala chokhudzidwa ndi chinyezi cha chilengedwe. Kugwiritsa ntchito nthawi yayitali kumakhala ndi dzimbiri, zomwe zimawonjezera kuwonongeka kwa kulondola. pa

Kutsimikizira kusiyana kwa magwiridwe antchito muzogwiritsa ntchito

M'munda wa 3C electronic precision component component, bizinezi yodziwika bwino idachita mayeso ofananiza pa magwiridwe antchito amitundu iwiri yazida zakuthupi. Pakuyesaku, makina awiri a picosecond laser oyika chizindikiro omwe ali ndi kasinthidwe komweko anali ndi zida za granite ndi zitsulo zotayidwa kuti azidula ndikuyika chizindikiro pagalasi la zowonera pafoni yam'manja ndi m'lifupi mwake 0.1mm. Pambuyo pa maola 200 akukonzedwa mosalekeza, kuchuluka kwa kusungirako kulondola kwa zida za granite kunali 98.7%, pomwe zida zachitsulo zotayira zinali 86.3% yokha. Mphepete mwa galasi lopangidwa ndi womalizayo adawonetsa zolakwika zowoneka bwino za macheka. pa

Popanga zigawo zamlengalenga, deta yowunika kwa nthawi yayitali ya bungwe linalake la kafukufuku imasonyeza bwino kusiyana kwake: Makina osindikizira a laser okhala ndi maziko a granite ali ndi kuwonjezereka kowonjezereka kosachepera 3μm mkati mwa moyo wautumiki wa zaka zisanu; Komabe, patatha zaka zitatu, kulakwitsa kwa makina opangira chitsulo chifukwa cha mapindikidwe a m'munsi kwadutsa muyeso wa ± 10μm, ndikuwongolera kulondola kwa makina onse kuyenera kuchitika. pa

Malangizo owonjezera zisudzo

Ngati mabizinesi amatenga kukhazikika kokhazikika komanso kwanthawi yayitali monga momwe amafunira, makamaka m'magawo monga tchipisi ta semiconductor ndi zida zowoneka bwino, zoyambira za granite, ndi kukhazikika kwawo kwamafuta komanso kukana kugwedezeka, ndi njira yabwino yokweza. Ngakhale mtengo wake woyamba wogula ndi 30% mpaka 50% wokwera kuposa wachitsulo choponyedwa, malingana ndi mtengo wanthawi zonse wa moyo, kuchepetsedwa kwafupipafupi kuwongolera molondola komanso kutsika kwa zida pakukonza kumatha kupititsa patsogolo phindu lonse. Pazochitika zogwiritsa ntchito zomwe zili ndi zofunikira zochepa pakukonza bwino komanso ndalama zochepa, maziko achitsulo amatha kugwiritsidwabe ntchito ngati njira yosinthira potengera kuwongolera komwe kumagwiritsidwa ntchito. pa

Poyerekeza mwadongosolo mikhalidwe yochepetsetsa ya granite ndi chitsulo choponyedwa mu picosecond-level processing, zitha kuwoneka kuti kusankha zoyambira zoyenera ndizofunikira kwambiri pakuwongolera kulondola komanso kudalirika kwa makina ojambulira laser. Mabizinesi akuyenera, potengera zofuna zawo zaukadaulo komanso kutengera mtengo wake, kupanga zisankho zasayansi pamalingaliro okweza kuti apange maziko olimba a zida zopangira zida zapamwamba. pa

Nthawi yotumiza: May-22-2025