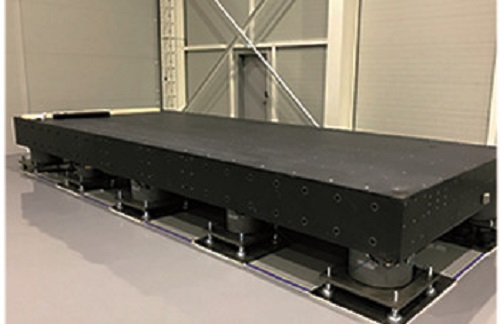

Pankhani yoyesa ma semiconductor, kusankha zinthu zomwe zili papulatifomu yoyesera kumachita gawo lofunika kwambiri pa kulondola kwa mayeso ndi kukhazikika kwa zida. Poyerekeza ndi zipangizo zachikhalidwe zachitsulo chopangidwa ndi chitsulo, granite ikukhala chisankho chabwino kwambiri pamapulatifomu oyesera ma semiconductor chifukwa cha magwiridwe ake abwino kwambiri.

Kukana dzimbiri kwabwino kwambiri kumatsimikizira kuti ntchito yake ndi yokhazikika kwa nthawi yayitali

Pa nthawi yoyesera semiconductor, nthawi zambiri pamakhala zinthu zosiyanasiyana zomwe zimagwiritsidwa ntchito, monga potassium hydroxide (KOH) solution yomwe imagwiritsidwa ntchito popanga photoresist, ndi zinthu zomwe zimawononga kwambiri monga hydrofluoric acid (HF) ndi nitric acid (HNO₃) mu etching process. Chitsulo chopangidwa ndi cast chimapangidwira makamaka ndi zinthu zachitsulo. Mu malo otere a mankhwala, zochitika zochepetsa okosijeni zimakhala zofala kwambiri. Maatomu achitsulo amataya ma elekitironi ndipo amakumana ndi zinthu zosunthika ndi acidic mu solution, zomwe zimapangitsa kuti pamwamba paziwonongeke mofulumira, kupanga dzimbiri ndi kutsika, ndikuwononga kusalala ndi kulondola kwa pulatifomu.

Mosiyana ndi zimenezi, kapangidwe ka mchere ka granite kamapatsa granite mphamvu yolimbana ndi dzimbiri. Gawo lake lalikulu, quartz (SiO₂), lili ndi mphamvu zokhazikika kwambiri za mankhwala ndipo siligwirizana ndi ma acid ndi ma base wamba. Michere monga feldspar ndi yopanda mphamvu m'malo ambiri a mankhwala. Kuyesa kwakukulu kwawonetsa kuti m'malo omwewo oyeserera a semiconductor detection chemical resistance, kukana kwa mankhwala a granite ndi kokwera nthawi zoposa 15 kuposa kwa chitsulo chopangidwa. Izi zikutanthauza kuti kugwiritsa ntchito nsanja za granite kungachepetse kwambiri kuchuluka ndi mtengo wokonza zida zomwe zimayambitsidwa ndi dzimbiri, kukulitsa moyo wa ntchito ya zidazo, ndikuwonetsetsa kuti kulondola kwa kuzindikira kukhazikika kwa nthawi yayitali.

Kukhazikika kwambiri, kukwaniritsa zofunikira pakuzindikira molondola pamlingo wa nanometer

Kuyesa kwa semiconductor kuli ndi zofunikira kwambiri kuti nsanjayo ikhale yokhazikika ndipo imafunika kuyeza molondola mawonekedwe a chip pa nanoscale. Kuchuluka kwa kutentha kwa chitsulo chopangidwa ndi chitsulo chopangidwa ndi chitsulo ndi kwakukulu, pafupifupi 10-12 × 10⁻⁶/℃. Kutentha komwe kumachitika chifukwa cha kugwiritsa ntchito zida zodziwira kapena kusinthasintha kwa kutentha kwa malo ozungulira kumayambitsa kufalikira kwakukulu kwa kutentha ndi kupindika kwa nsanja yachitsulo chopangidwa ndi chitsulo chopangidwa ndi chitsulo, zomwe zimapangitsa kuti pakhale kusiyana pakati pa probe yodziwira ndi chip ndikukhudza kulondola kwa muyeso.

Kuchuluka kwa kutentha kwa granite ndi 0.6-5×10⁻⁶/℃ kokha, komwe ndi kachigawo kakang'ono kapena kocheperako kuposa ka chitsulo chopangidwa. Kapangidwe kake ndi kokhuthala. Kupsinjika kwamkati kwachotsedwa makamaka chifukwa cha ukalamba wachilengedwe kwa nthawi yayitali ndipo kumakhudzidwa pang'ono ndi kusintha kwa kutentha. Kuphatikiza apo, granite ili ndi kulimba kwamphamvu, komwe kuli kolimba nthawi 2 mpaka 3 kuposa kwa chitsulo chopangidwa (chofanana ndi HRC > 51), komwe kumatha kukana bwino kugwedezeka ndi kugwedezeka kwakunja ndikusunga kusalala ndi kulunjika kwa nsanjayo. Mwachitsanzo, pakuzindikira kwa chip circuit yolondola kwambiri, nsanja ya granite imatha kuwongolera cholakwika cha flatness mkati mwa ±0.5μm/m, kuonetsetsa kuti zida zodziwira zimathabe kuzindikira molondola kwa nanoscale m'malo ovuta.

Kapangidwe kabwino kwambiri kotsutsana ndi maginito, komwe kamapanga malo odziwika bwino

Zigawo zamagetsi ndi masensa mu zida zoyesera za semiconductor zimakhala zovuta kwambiri kusokonezedwa ndi maginito. Chitsulo chopangidwa ndi chitsulo chili ndi mphamvu inayake ya maginito. Mu malo ogwiritsira ntchito maginito, chimapanga mphamvu ya maginito yomwe imayambitsidwa, yomwe imasokoneza zizindikiro za maginito za zida zodziwira, zomwe zimapangitsa kuti zizindikirozo zisokonezeke komanso deta yosadziwika bwino.

Koma granite ndi chinthu chotsutsana ndi maginito ndipo sichimagawidwa ndi maginito akunja. Ma electron amkati amapezeka awiriawiri mkati mwa ma bond a mankhwala, ndipo kapangidwe kake ndi kokhazikika, kosakhudzidwa ndi mphamvu zamagetsi zakunja. Mu malo amphamvu a maginito a 10mT, mphamvu ya maginito yomwe imabwera pamwamba pa granite ndi yochepera 0.001mT, pomwe pamwamba pa chitsulo chopangidwa ndi chitsulo ndi yokwera kuposa 8mT. Izi zimathandiza nsanja ya granite kupanga malo oyera amagetsi a zida zodziwira, makamaka oyenera zochitika zomwe zili ndi zofunikira kwambiri pa phokoso lamagetsi monga kuzindikira kwa quantum chip ndi kuzindikira kwa analog circuit kolondola kwambiri, zomwe zimapangitsa kuti zotsatira zozindikirika zikhale zodalirika komanso zogwirizana.

Pakupanga mapulatifomu oyesera ma semiconductor, granite yapambana kwambiri zipangizo zachitsulo chifukwa cha ubwino wake waukulu monga kukana dzimbiri, kukhazikika komanso kukana maginito. Pamene ukadaulo wa ma semiconductor ukupita patsogolo kwambiri, granite idzakhala ndi gawo lofunika kwambiri pakuwonetsetsa kuti zida zoyesera zikugwira ntchito bwino komanso kupititsa patsogolo makampani opanga ma semiconductor.

Nthawi yotumizira: Meyi-15-2025