Pofunafuna mosalekeza ma microchip ang'onoang'ono, othamanga, komanso amphamvu kwambiri, zofuna zomwe zimayikidwa pa Wafer Processing Equipment zikukwera kufika pamlingo wolondola womwe kale unkaganiziridwa kuti sungatheke. Pamene zinthu zikuchepa kulowa mu gawo la nanometer ya manambala amodzi, kukhazikika kwa nsanja yonse yopanga zinthu kumakhala kofunikira kwambiri. Apa, pansi pa mitundu yosiyanasiyana ya lasers, zipinda zotsukira, ndi makina a robotic, pomwe zinthu zakale—granite yachilengedwe—zimawonekera ngati chinthu chofunikira kwambiri pakuchita bwino kwa semiconductor yamakono. Mafotokozedwe, uinjiniya, ndi kupezeka kwa zigawo za granite za OEM zolondola kwambiri komanso bedi la makina a granite la OEM si zofunikira zaukadaulo zokha; ndizo maziko a umphumphu wa ntchito.

Udindo wa makina oyambira mu dongosolo lililonse lolondola kwambiri ndikupereka malo okhazikika komanso okhazikika. Mu malo osinthasintha komanso ofunikira kwambiri popanga ma semiconductor, komwe njira monga lithography, etching, ndi deposition zimachitika, kusintha pang'ono - ngakhale pamlingo wa sub-micron - kungayambitse kutayika kwakukulu kwa zokolola. Chifukwa chake, kusankha zinthu zoyambira, monga makina oyambira a Wafer Processing Equipment, ndi sitepe yosakambirana pakupanga.

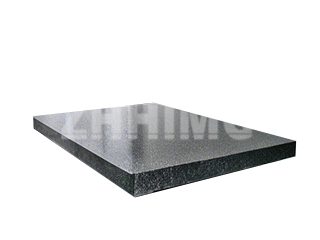

Ubwino Wachibadwa wa Granite Yachilengedwe

N’chifukwa chiyani granite yachilengedwe imagwira ntchito bwino kuposa zipangizo zopangidwa ndi akatswiri monga chitsulo chosungunuka, chitsulo, kapena zinthu zina zopangidwa mwaluso kwambiri? Yankho lake lili m’makhalidwe ake apadera, akale achilengedwe omwe ndi oyenera bwino malo osakhululuka a makina olondola.

1. Kuchepetsa Kugwedezeka Kwapadera (Kudzipatula ku Machitidwe Osinthasintha):

Kugwedezeka ndi mdani wa kupanga zinthu zazing'ono. Kaya zimapangidwa mkati mwa injini ndi zinthu zoyenda kapena kunja kwa chipinda chotsukira, kugwedezeka kulikonse kuyenera kuyamwa mwachangu. Granite ili ndi mphamvu yayikulu yamkati yochepetsera kutentha—yabwino kwambiri kuposa zitsulo. Izi zikutanthauza kuti mphamvu yamakina imachotsedwa mwachangu ngati kutentha, kuletsa kugwedezeka ndikuwonetsetsa kuti njira zofunika kwambiri zikuchitika papulatifomu yokhazikika. Izi ndizofunikira kwambiri kuti pakhale malo enieni ofunikira mu lithography yapamwamba kapena kuonetsetsa kuti zinthuzo zichotsedwa mofanana panthawi ya chemical mechanical planarization (CMP).

2. Kuwonjezeka kwa Kutentha kwa Near-Zero (Kusunga Umphumphu wa Kugwirizana):

Zipangizo Zopangira Ma Wafer nthawi zambiri zimakhala ndi kusinthasintha kwa kutentha, komwe kumachitika mozungulira komanso chifukwa cha njira. Zipangizo zachitsulo zimakula ndikuchepa kwambiri ndi kusintha kwa kutentha, zomwe zimapangitsa kuti kutentha kusunthike komanso kusakhazikika bwino kwa makina owonera kapena makina. Granite, makamaka granite wakuda, imawonetsa kuchuluka kochepa kwambiri kwa kutentha (CTE), pafupifupi 3 × 10⁻⁶/℃. Kukhazikika kwa kutentha kumeneku kumatsimikizira kuti kulondola kwa gawo la bedi la makina a granite ndi zida zina za granite za OEM kumakhalabe kofanana, kuchepetsa zolakwika za kutentha ndikutsimikizira kubwerezabwereza kwa muyeso pansi pa mikhalidwe yosiyanasiyana.

3. Kusalala Kwambiri ndi Kuuma:

Kudzera mu njira zamakono zolumikizira ndi kupukuta, granite yachilengedwe imatha kukhala yosalala pamwamba poyesedwa mu sub-microns - chofunikira chofunikira pa malo ofunikira omwe amagwiritsidwa ntchito powongolera mayendedwe molondola. Kuphatikiza apo, modulus yake yayikulu ya Young imapereka kuuma kwapadera komanso kosasunthika. Kukana kumeneku kutembenuka pansi pa katundu ndikofunikira, chifukwa maziko ake ayenera kuthandizira ma mota akuluakulu, magawo, ndi zomangamanga zovuta za Wafer Processing Equipment popanda kusintha koyezeka, ngakhale pazitali zazitali.

Kupanga Tsogolo: Zigawo za Granite za OEM ndi Msonkhano Wovuta

Kugwiritsa ntchito granite kwamakono kumapitirira kuposa ma plate osavuta pamwamba. Opanga zamakono masiku ano amafuna zigawo za granite za OEM zovuta komanso zopangidwa mwapadera. Izi zitha kuphatikizapo njanji zowongolera mpweya, ma vacuum chucks ovuta, zinthu zambiri zozungulira, ndi ma block oyika ma laser ndi optics. Zidutswa izi nthawi zambiri zimapangidwa ndi makina okhala ndi mawonekedwe ovuta a geometric, kuphatikiza mabowo obowoledwa kuti waya ulowe, zoyikapo ulusi kuti zikhazikike, ndi michira ya dovetail kapena mipata yokonzedwa bwino ya makina oyika.

Njira yopangira makina okonzera zinthu za Wafer Processing imayamba ndi makina akuluakulu a granite. Zigawo za granite zomwe zikutsatira zimalumikizidwa bwino kapena kulumikizidwa nazo pogwiritsa ntchito mankhwala apamwamba ochokera ku epoxy, gawo lofunika kwambiri lomwe limatsimikizira kuti kapangidwe kake konse kamagwira ntchito ngati chinthu chimodzi, chofanana. Kuphatikiza bwino kumafuna chisamaliro chapadera pa tsatanetsatane:

-

Kusintha: Zigawo ziyenera kupangidwa molingana ndi zomwe kasitomala akufuna, nthawi zambiri kuphatikizapo kuphatikiza zinthu zopanda granite monga mizere yozizira ndi zomangira za sensor mwachindunji mu kapangidwe kake.

-

Chitsimikizo cha Ubwino: Gawo lililonse limafuna kuwongolera bwino kwambiri khalidwe, kuphatikizapo kusalala, kulunjika, ndi kutsimikizira squareness pogwiritsa ntchito ma CMM ndi ma laser interferometer, kuonetsetsa kuti akukwaniritsa miyezo yokhwima ya ISO ndi mayiko ena ya metrology ndi kulondola.

-

Mgwirizano wa Ogulitsa: Kusankha wogulitsa zigawo za granite wa OEM ndi mgwirizano. Kumafuna kumvetsetsa bwino momwe semiconductor imagwiritsidwira ntchito, kuthekera kosankha miyala yaiwisi yapamwamba kwambiri, komanso luso lopanga makina ndi kusonkhanitsa nyumba zovuta kuti zigwirizane ndi nanometer tolerances.

Pomaliza, ngakhale kuti microchip yomalizidwa ndi luso la anthu, kupangidwa kwake kumadalira kukhazikika chete komwe kumaperekedwa ndi miyala yachilengedwe. Kugwiritsa ntchito granite mwaluso ngati chinthu chofunikira kwambiri pa bedi la makina a granite ndi zida zina zapadera za granite za OEM ndi chinthu chofunikira kwambiri pakukweza malire a miniaturization. Kwa opanga zida zopangira Wafer, kugwirizana ndi katswiri wa zomangamanga za granite zolondola kwambiri ndi sitepe yoyamba komanso yofunika kwambiri yopezera mwayi wopikisana pamsika wapadziko lonse wa semiconductor.

Nthawi yotumizira: Disembala-01-2025